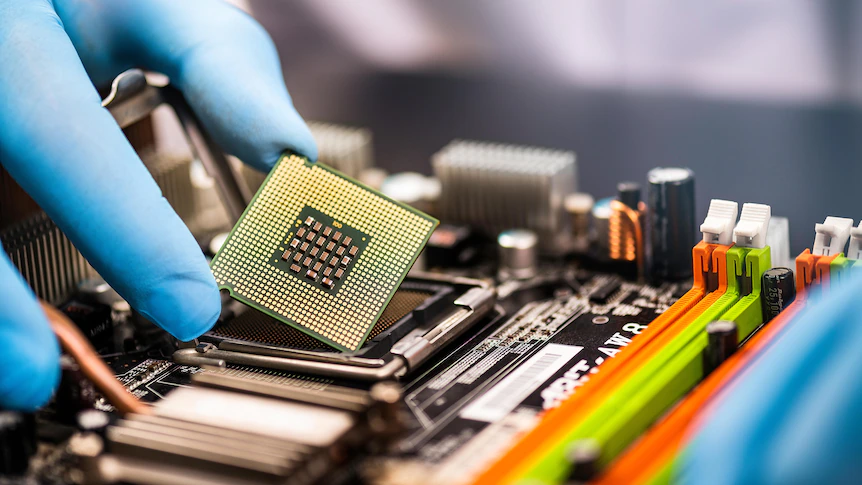

Semiconductors or what we better know as microchips or integrated circuits (ICs) are used in the production of a variety of products ranging from computers, cell phones to cars, fridges, and much more.

These chips may be the tiniest yet most important product ever manufactured on a global scale.

The microchips are essentially the backbone of almost all modern equipment. Mostly made up of silicon and known to conduct electricity more than that of an insulator, like rubber but less than that of a conductor, like metal.

This implies that controlling their electrical conductivity can be used to switch or amplify electrical signals which makes their use quite significant in electrical devices.

Chips are known to make a device smarter.

Memory chips used to store data are relatively simple and cheap. Logic chips, which are used to run programs and act as the brains of a device, are relatively complex and expensive.

At present, the world is facing a drastic shortage of these chips causing substantial stress over the tech giants including companies like Apple and Samsung leading them to delay their new releases.

‘Taiwan Semiconductor Manufacturing Co., South Korea’s Samsung Electronics Co. and Intel Corp.’ are the dominant manufacturers in this industry.

Taiwan is known to be the leading supplier of semiconductors, accounting for 70% of the exports but a recent drought and the pandemic crisis have relatively reduced the production in comparison to the rising demand.

The Semiconductor industry requires a large amount of water in the manufacturing process.

The drought has forced the manufacturers to scramble ways to ensure sufficient water supply and to use it economically.

Reasons for the shortage

1) Stockpiling

In May 2020, the Trump government imposed sanctions against Huawei Technologies, which obstructed the Chinese smartphone maker from acquiring semiconductors made with U.S. technology.

The blockade, which gave suppliers 120 days to comply, prompted Huawei to increase orders and hoard chips before the ban.

Further, other companies started stocking up chips too because they wanted to take the market share left by Huawei, another trigger for the shortage.

2) Businesses going online

The increasing covid spread and lockdown forced businesses to go online thus increasing the demand for PCs, laptops, and cellphones.

This surged an increase in chip demand beyond the projected level before the pandemic. A drastic rise was also seen in the sale of home appliances, all of which now come with customized chips.

3) Varying Predictions

The automakers had cut back on their workers and production during the early phase of a pandemic, they also canceled their orders for the semiconductors as a result too.

The supply rose suddenly during the later stages and the manufacturers couldn’t estimate how quickly car sales would rebound.

The production was still postponed because the chip manufacturers were busy supplying to the tech giants.

If the production doesn’t meet the growing demand, soon the world will be seeing a hike in the prices of gadgets, home appliances, and automobiles, all of which are highly dependent on the chips.

Amidst the shortage, Taiwan has exponentially increased the chip production along with US building plans to welcome TSMC and Samsung to set up new manufacturing chip plants in the US.

China is also relying on becoming self-sufficient in chip production to catch up as part of its efforts to reduce the country’s reliance on U.S. technology.

Also Checkout: How To Remove The Crown Icon On Discord